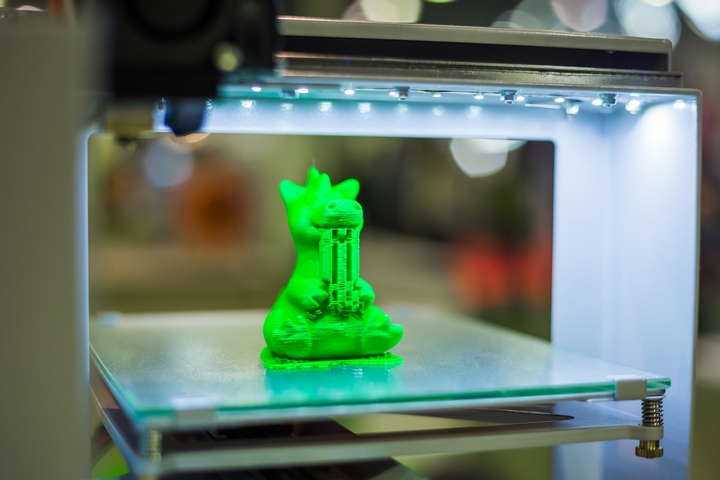

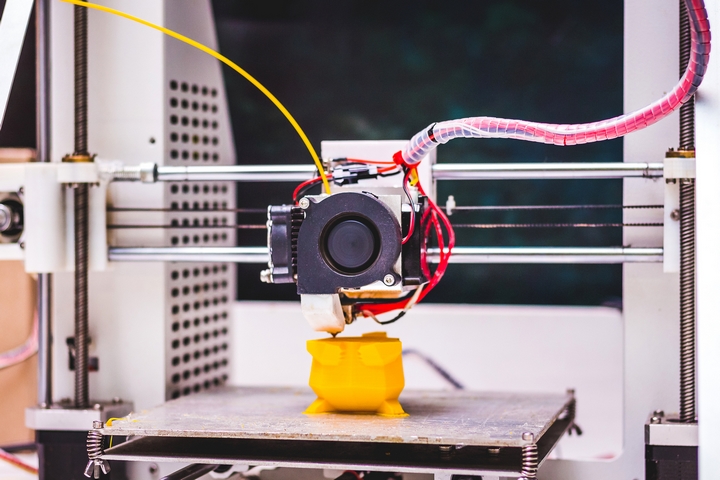

3D printing is the thing of the future! 3D printing can be used for personal uses or even to help with manufacturing within a range of industries. For instance, 3D printing has become more commonly used in the jewelry industry to make moulds for jewelry, and even the beads themselves. Furthermore, 3D printing is becoming very popular in the customizable gifts industry, where it is used to make personalized items such as sculptures, Christmas ornaments, photo frames, art, and many more.

3D printing is even branching out to the food industry as it is aiding with the production of sweets such as chocolate. In the manufacturing industry, 3D printing is popular for making tool and mechanics moulds. Needless to say, 3D printing is taking numerous industries by storm. For more information, we researched the five best 3D printing tips and tricks:

1. Leveling the Bed and Setting Nozzle Height Correctly

3D printing is heavily dependent on the positioning of the nozzle and the level of the bed. The most important way to improve 3D printing is to ensure that the bed is leveled appropriately and the nozzle is adjusted accordingly. In order to test whether this is put in place correctly, try using a sheet of plain paper or a feeler gauge to check the distance between the bed and the nozzle.

You will know that the distance is correct, as the paper or gauge will barely have any resistance when it is pulled free, and when it can go under the nozzle without any difficulty. It might be worthwhile to repeat this check a few times until you are comfortable.

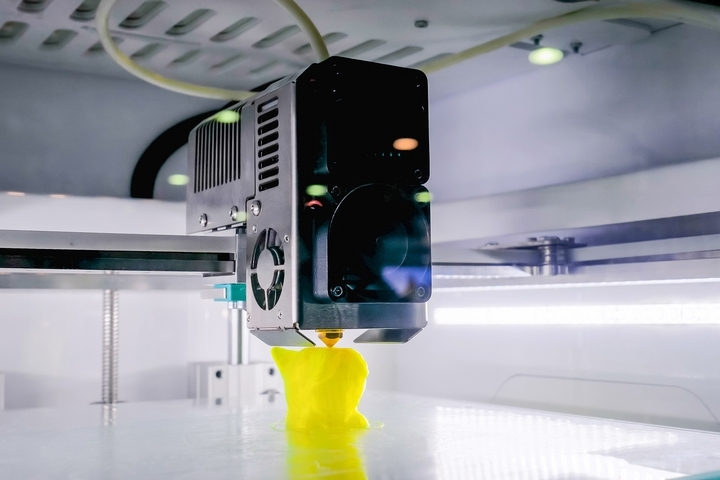

2. Ensure the Nozzle is the Right Temperature

Many people don’t know about the fact that the nozzle temperature is directly related to the look of the print. If the nozzle is too warm, it can cause stringy portions across the printing. This is particularly visible in very tall pieces, where high temperatures can melt lower layers and this results in a loss of integrity across the entire structure. When you are printing tall structures, ensure that you create a cube on the opposite side of the build plate.

This cube allows the hot nozzle to be removed from creating the tall structure and it gives it a chance to cool down. If you do end up with oozy portions in your structure, you can always get creative about the reason behind it. Swamp structure anyone?

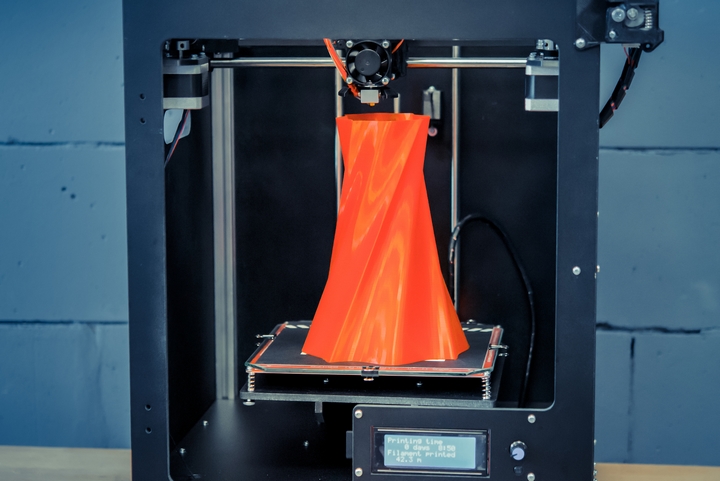

3. Figure out the Ideal Bed Temperature

The temperature of the build plate, which is also often referred to as the “bed,” helps control print adhesion. As the machine prints, each layer cools and shrinks a little bit. Therefore, the layer above it contracts slightly, causing the edges of the print job to separate from the plate.

When the temperature is too high, the model can develop what it referred to as “elephant feet,” which means that the bottom of the project widens and expands. If this happens, it signals that you need to reduce the temperature of the bed before you embark on your next printing project.

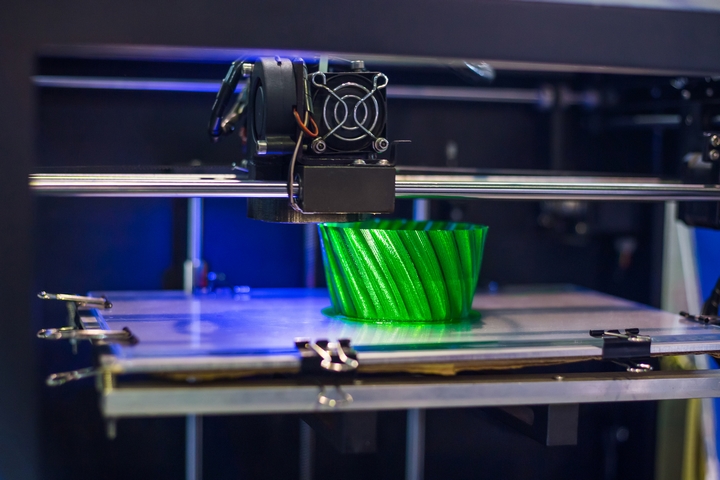

4. Get Comfortable with Build Plates

One of the most important 3D printing tips and tricks is get familiar with build plates. Build plates help the printer create a variety of textures at the bottom of the print job. In order to make the texture come through, consider using a spray or glue at the bottom of the project. This will ensure that it sticks effectively to the print.

However, make sure you don’t use too much, as this could leave dents or malformations. Using too much glue or spray will also make it difficult to remove the print and if you end up forcing it off, you could damage the print or the machine. The best approach is to continue to experiment with your machine and see what works best.

5. Pay Attention to Maintenance Warnings and Updates

Each printer comes with its own unique features and maintenance instructions. It is your job to keep on top of that. Some key maintenance activities include cleaning and lubricating the rails as per manufacturer’s recommendations. As well, always keep an eye out for any inconsistencies, poorer quality print jobs, and if there is evidence of any wobble in the frame. Also, take time to ensure that the blots are tight and all 90-degree angles are square. It also helps to take a peek at the manufacturer’s website around any system updates or warnings.

3D printing can be both a fun hobby and a profitable business venture. Despite any printing fails, ensure that you persevere! It may be tricky to use at first, but it will be second nature once you get comfortable. Happy printing!